Enercare Center in Toronto, Canada

Exhibition room: # 1, 100 princes' Blvd, Toronto, on M6K 3C3 Canada Display the cardPlace area: 20,000 square meters Country and region: North America Canada The center of Enercare in Toronto, Canada, was previously a direct energy center and was originally a national shopping center. It is an exhibition complex located at the Toronto Exhibition Center, Ontario, Canada. It is used by the Canadian National Exhibition and the Royal Winter Agricultural Fair as well as various trade fairs.The rights to name the complex currently belong to Energy Services Company Enercare, a subsidiary of Brookfield Infrastructure Partners. It is located west of Prince Gate at the eastern end of the exhibition hall, which formerly houses the tram buckle and the open space. The new building occupies the facade of Prince Avenue and connects with the existing gymnasium and industrial buildings (also called agricultural appendices), forming a large interconnected exhibition complex. Exhibition calendar all February 2025 March 2025 April 2025 May 2025…

Hotel La Ting Hotel, Westminster Bridge, London, United Kingdom

Exhibition room: 200 Westminster Bridge RD, London SE1 7UT UK Display the cardPlace area: 6000 square meters Country and region: Europe and the United Kingdom The Westminster Bridge Hotel London, England, is located in the heart of London, a few steps from the London Aquarium and Nightingale Museum. The hotel is close to London Eye and Big Ben. The rooms offer a minibar and a plasma TV, and you will surely find the comfort of your house on the go. Free wireless internet access allows you to stay in touch with friends; Cables can meet your entertainment needs. The bathroom is delivered with a separate bathtub and a shower with free toiletries and a hair dryer. Exhibition calendar all February 2025 March 2025 April 2025 May 2025 June 2025 July 2025 August 2025 September 2025 October 2025 SO next year Canjam Global Exhibition of Hifi headphones in London, United Kingdom 2025.07.19-07.20 There is still a way to go 109 sky…

Marriott Hotel in Shanghai

Exhibition room: N ° 555, Tibet Middle Road, Renmin Square, Huangpu district, Shanghai Display the cardPlace area: 6000 square meters Country and region: Shanghai, China The Shanghai Marriott hotel is tailor -made by the famous design company in the world. Its large and transcendent building, combined with the concept of modern design, will be a new interpretation of discreet luxury in Shanghai, creating extraordinary hospitality for an exceptional elite group with exceptional taste and confidence. JW Marriott belongs to the luxury brand of Marriott International Group, while JW Marriott Marriott Marriott is an upgrading of the JW Marriott brand, which has advantages in terms of choice of geographic location, architectural design and uniqueness, hotel scale and diversified catering experience.The hotel has 6 catering options, including a full -time restaurant, a Chinese restaurant, a western restaurant, a tea room, a bar and a roof bar. Customers can taste a rich world cuisine in the full -time restaurant - Hang Train Kitchen,…

Pan Pacific Hotel Singapore

Exhibition room: 7 Raffles BLVD, Singapore 039595 Display the cardPlace area: 6000 square meters Country and region: Singapore, Asia The Pan Pacific Five-Star Singapore hotel is connected to the Marina Square Mall and the Suntec Convention Center. Located at the entrance to the central districts and financial districts of Singapore, the hotel offers an outdoor swimming pool where customers can dine at 8 catering options or have a drink at the bar. Free Wi-Fi is available throughout the property. The hotel is 800 meters from esplanade - Theaters by the bay, and the gardens by the bay are 1.1 km. The National Gallery Singapore, Victoria Theater and Asian Civilizations Museum are all within 1.3 km. Pan Pacific Singapore is 20 km from Changi Singapore airport. The air -conditioned rooms of Pan Pacific Singapore have floor -to -ceiling windows and panoramic views. All rooms are equipped with a flat -screen satellite TV and a work office. The bathroom is delivered with…

Marriott Hotel, Hong Kong Ocean Park

Exhibition room: Aberdeen, 180, Wong Chuk Hang Rd, Aberdeen Display the cardPlace area: 8000 square meters Country and region: Hong Kong, China Located on the south coast of Hong Kong Island, the Hong Kong Marriott Marine Park hotel is the perfect base for your next visit to this dynamic city. Located at the entrance to Hong Kong Ocean Park, the hotel has 471 rooms and suites that combine modern design with a natural style decoration and a versatile event space including a ballroom without spacious column. When you arrive, enter our welcome room and you will be shocked by an aquarium 16 meters high. Choose from a variety of exterior style restoration options to enjoy a view of lush gardens and the lagoon. Exhibition calendar all December 2024 January 2025 February 2025 March 2025 April 2025 May 2025 June 2025 July 2025 August 2025 SO next year

Marriott Hotel in Dallas, USA

Exhibition room: 650 N Pearl St, Dallas, TX 75201 United States Display the cardPlace area: 8000 square meters Country and region: North America in the United States Located in the heart of Dallas, just a 7 -minute walk from the Dallas Museum of Art, the Marriott Dallas hotel offers rooms with a 37 -inch flat -screen TV. Each spacious hotel room offers wifi, cable television, coffee manufacturing facilities and a safe. It is decorated in modern times and carpet floors. All customers of the Dallas Marriott hotel have free access to the gymnasium, open 24 hours a day. The hotel has an atrium with a unique view of the city roofs. The Dallas world aquarium is only 5 minutes away and the Dallas zoo is 5.2 miles away. Exhibition calendar all December 2024 January 2025 February 2025 March 2025 April 2025 May 2025 June 2025 July 2025 August 2025 SO next year Canjam Global Exhibition of Hifi headphones in Dallas,…

Kazakhstan Usti Kamenogorsk Alexander Stadium

Exhibition room: XJ48 + M92, Abay Ave, Oskemen 070000 Kazakhstan Display the cardPlace area: 20,000 square meters Country and region: Kazakhstan, Asia In 2010, the stadium was renamed after the Soviet Union and the Kazakhstan hockey player, Boris Alexandrov.This is the first stadium in Kazakhstan to use architecture tras. It was also the first stadium of Ice Ice Ice Hockey in the Soviet Union to build a training ground. Initially, the main arena could accommodate 5,200 spectators. In 2001, Kazzinc spent $ 3 million to rebuild the arena. Exhibition calendar all December 2024 January 2025 February 2025 March 2025 April 2025 May 2025 June 2025 July 2025 August 2025 SO next year Mintch Kazakhstan electricity and energy exhibition 2025.05.21-05.23 There is still a way to go 53 sky Stand Tickets Newspaper Mintch Kazakhstan Construction Machinery and Mining Machinery Exhibition 2025.05.21-05.23 There is still a way to go 53 sky Stand Tickets Newspaper

Hilton Hotel Kuala Lumpur, Malaysia

Exhibition room: 3, Jalan Spesen Sentral, Kuala Lumpur Sentral, 50470 Kuala Lumpur, Persekutuan Wilayah Kuala Lumpur, Malaysia Display the cardPlace area: 0 square meters Country and region: Asia Malaysia Hilton Malaysia, Kuala Lumpur, Malaysia, found us next to the Kuala Lumpur central transport center, and is 28 minutes by train at high speed at Kuala Lumpur International Airport. Mid Valley Megamall, Kuala Lumpur Pavilion, Central Market, Petro Malaysia Twin Towers, Kuala Lumpur Tower, Kuala Lumpur Bird Park and Chinatown are about 10 minutes by car. We offer a swimming pool with water slides, nine restaurants, a full service spa, a meeting space and wedding places. Exhibition calendar all December 2024 January 2025 February 2025 March 2025 April 2025 May 2025 June 2025 July 2025 August 2025 SO next year

Simultaneous meetings | 60+ high quality forums, more than 200 celebrities in the industry are in place!

In 2025, when challenges and opportunities coexist, how can the manufacturing industry find a way out in the changing situation? Anchor"New trends, new processes, new technologies, new technologies, new ideas",,2025 ITS Shenzhen Industrial Exhibition and high -end industry industryAt the same time, we will work with many industry partners to hold60+Conferences and series of high quality forums, FocusPrecision manufacturing, intelligent electronic manufacturing, new energy vehicles, medical devices, smart manufacturingFive major tracks, invitations200The guests have held an in -depth dialogue on site, shared a practical experience and prospective ideas, and jointly explored new paths for high quality development of companies.01Big Nomes lineage sortFace -to -face communication on site02All strategies for the same periodPlan the calendar of meetings in advanceMarch 26March 27March 283.26-29 Shenzhen International Convention and Exhibition Center (BAOAN)Tomorrow ShenzhenAttend the opening exhibition of the manufacturing industry References: Exhibition Shenzhen International Metal Machine Tools Tools ItesOrganization area: GuangdongDate of exhibition: March 26, 2025-March 29 ArchOpening and closing time: 09: 00-18: 00Organization…

2025 Most complete ITES exhibition guide! Free Metro Exhibition Hall

2025 ITS Shenzhen Industrial Exhibition and high -end industry industryFutureDirect the development of intelligent manufacturing with advanced technologies and market informationEmpower the accelerated training of new quality productivityBest industrial brandsAndProfessional forumwaiting for youOffer【The most complete exhibition guide】Favorite, before and do not lose yourself when visiting the exhibition!(Exhibition time) March 26-29 9: 00-17: 00(The last day of the exhibition at 3:00 p.m.)【Exhibition location】 Congress and International Exhibition Center in Shenzhen (Baoan)2025 ITES exposure content ↓ Click to display the stand card and easily navigate the stand location ↓ 01How to register for admission?During the exhibitionPublic quotient"Electronic ticket QR code"Enter the museum after security checkFriends who have not yet obtained "exhibition tickets"Move your fingersClick on the image belowFree tickets!02How to get to the exhibition hall quickly?AutonomousIf you choose to drive alone, please visit the museum.Shenzhen International Convention and Exhibition Center P1, P2, P3, P4, P5, P8, P9 Entrance to the underground car park or doors 1, 2, 4, 16, 16Non -deep license…

Exhibition recommendation | The exhibition of the Munich Shanghai 2025 electronic production equipment is about to open in March, and will know all the highlights of the exhibition!

The exposure of Munich Shanghai electronic production equipment is a crucial display and exchange platform for the electronic intelligent manufacturing industry.March 26 to 28, 2025existShanghai New International Expo Center (E1-E5 & W1-W4 Hall)Return greatly again. This exhibition is a large scale and will reachAlmost 100,000 square metersThe site should attractOver 1,000 companiesHigh -quality companies in the electronic manufacturing industry join, and these companies will display products and technologies covering the entire chain of the electronic manufacturing industry, in particular electronic and chemical materials, distribution and binding services, electronic mounting technology, wire processing and manufacturing of connectors, manufacturing of components, movement control and control of components, control of the movements, control of movements Intelligence, intelligence, intelligence of components, control of movements and control of professional movements and techniques, industrialists, intelligence robots, switches, connection companions, control of movements and control of movements and technicians, intelligence technicians, intelligence robots, switches, intelligence objects, storage, etc.List of exhibitors and the announced pavilion floor planThis exhibition…

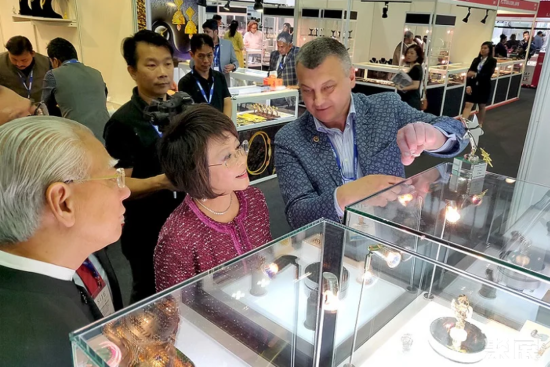

Stand and map of the Singapore 2025 jewelry exhibition stand

As the Singapore jewelry exhibition approaches, to help exhibitors in the jewelry industry to reserve their gentle stands, Juzhan.com provides a detailed stand booking guide. Stand type and price Standard booth: provides basic stand installations, including exhibition tables, exhibition tables, chairs, lighting, etc., suitable for small businesses or businesses participating in the exhibition for the first time. The prices vary depending on the area and the location of the stand. Light diving booth: No installation is provided. The price is calculated in square meters and also varies according to the various locations. Reservation process Complete the request form: Complete the online stand application form to provide basic information on business and stand needs. Select a stand: Select the location of the desired stand depending on the stand layout diagram and confirm the stand type and the area. Submit the request: submit the stand application form and related information, pending examination by the organizing committee. Sign a contract: once the examination…

How much does it cost to buy tickets for the US US work protection exhibition?

The highly anticipated exhibition for the protection of American labor will take place at a Congress and National Exhibition Center in Orlando in the United States on July 24, 2025, offering a precious communication platform for 24,500 visitors to the labor protection industry and 600 participating companies. US exhibition on labor protection Exhibition time: 2025.07.22-07.24 Exhibition room: Orlando National Convention and Exhibition Center, United States Orlando, United States Orlando Address: 9800 International Drive Orlando, FL 32819-8199 USA Exhibition scale: Area Exhibition: American Society of Safety Experts Experts Experts Experts Experts Purchase address Tickets address for the United States Labor Protection Exhibition Ticket reservation guide: 1. Visit the official site of the United States exhibition on the protection of work or the exhibition page of Juzhan.com. 2. Click on the "Remalogue of tickets" button or "Apply" to enter the reservation page. 3. Fill in your personal information based on prompts, including the name, contact number, identification number, etc. 4. Submit an…

2025 Spanish exhibition of natural foods and raw materials – European health products Exhibition of visitors and precautions

The exposure of European health products in natural food and Spanish raw materials - European health products will take place in Barcelona Exhibition Center in Spain on 2025.05.20-05.22. Pre-registered address Spanish exhibition of natural foods and raw materials - Exhibition of European health products Ticket information Exhibition ticket2025.05.20-05.22 2000.00 yuan Actual pre-registration 1. Real-Name Authentication: Almost all exhibitions require the audience to complete real-name registration in advance, fill in the real name, id number, mobile phone number and other information, and ensure that the original id card or corresponding certificate (such as passports, hong kong, macao and taiwan passes) Carried on-site Verification 2. Time-Sharing Appointment: some exhibitions Need to choose a specific Visit Date. If the supplement Period is not selected or miss, they may not be able to enter the coming 3. Pre-recorder Deadline: Some exhibitions require the Audience to complete the Pre-Registration at The Latest Before 24:00 On The Day Before the Exhibition, Otherwise they will not be…

2025 Conference and clinical veterinary precautions for small East-West animals

The exposure of the Small Animal 2025 clinical veterinary conference of 2025 will take place in the Xiamen International Convention and Exhibition Center on 2025.05.21-05.23. Online pre-registration is currently in full swing. Pre-registered address Public pre-registration at the exhibition of the clinical veterinary conference of small and western animals Ticket information Exhibition ticket2025.05.21-05.23 130.00 yuan Actual pre-registration 1. Real authentication: Almost all exhibitions require the public to end in advance real registration, fill out the actual name, identification number, mobile phone number and other information, and ensure that the original identity card or the corresponding certificate (such as passports, Hong Kong, Macao and Taiwan pass) should be transported to the specific site. If the appointment period is not selected or missed, they may not be able to enter the site 3. Pré-registration deadline: some exhibitions require that the public end the pre-registration at the latest before 24:00 the day before the exhibition, otherwise they will not be able to enter…

2025 Iraq Erbil Construction, construction and municipal equipment

The Iraq Erbil Construction, Construction and Municipal Equipal exhibition in Iraq Erbil will be held at Iraq Erbil International Exhibition Center at 2025.05.20-05.23. Online pre-registration is currently in full swing. Pre-registered address Pre-registration of visitors to Erbil, Iraq Construction, Construction and Municipal Equipment Exhibition Ticket information Exhibition ticket2025.05.20-05.23 300.00 yuan Actual pre-registration 1. Real authentication: Almost all exhibitions require the public to end in advance real registration, fill out the actual name, identification number, mobile phone number and other information, and ensure that the original identity card or the corresponding certificate (such as passports, Hong Kong, Macao and Taiwan pass) should be transported to the specific site. If the appointment period is not selected or missed, they may not be able to enter place 3. Pré-registration deadline: some exhibitions require that the public end the pre-registration at the latest before 24:00 the day before the exhibition, otherwise they will not be able to enter the site the same day. 4.…

Time and place for the beauty exhibition of Vietnam Ho Chi Minh 2025

Beauty exhibition ho chi minh, Vietnam Host times: 2025.07.24-07.26 Halle of experience: Saigon Convention and Exhibition Center, Ho Chi Minh, Vietnam, Organizer: Lawrence S. Ting Vietnam Scale Nguyen Van Linh Parkway, Dist. The highly anticipated exhibition of the beauty of Vietnam Ho Chi Minh in 2025 will be held at the Saigon Convention and Exhibition Center in Ho Chi Minh, Vietnam, from 24 to 07.26 July, offering a precious communication platform for the beauty and hairstyle industry, allowing 10,750 participants to adapt to industry trends and explore the latest technologies. Exhibition range: Perfume and makeup, personal treatments, natural care products, professional skin care products, body beauty products, Spa beauty instruments and toolsHairdressing salon products, Instruments and Tools of Hairdressing Salon, Art Products, Professional Care, Packaging and Production Instruments in Nail TheatersBeauty, hairstyle, nail raw materials, food and drinks, OEM / ODM, etc.(Copyright of this content belongs to Juzhan, and the transfer is prohibited without consent) Introduction to the Ho Chi…

2025 American High Point Home Textiles and Leather Exhibition Visitor Recording and Recording Method

The American High Point Home Textile and leather exhibition take place at the American High Point Center and at the exhibition center on 2025.05.20-05.22. Pre-registered address Public pre-registration at the American High Point Home Textiles and Leather Exhibition Ticket information Exhibition ticket2025.05.20-05.22 600.00 yuan Actual pre-registration 1. Real-Name Authentication: Almost all exhibitions require the audience to complete real-name registration in advance, fill in the real name, id number, mobile phone number and other information, and ensure that the original id card or corresponding certificate (such as passports, hong kong, macao and taiwan passes) Carried on-site Verification 2. Time-Sharing Appointment: some exhibitions Need to choose a specific Visit Date. If the supplement Period is not selected or miss, they may not be able to enter the coming 3. Pre-recorder Deadline: Some exhibitions require the Audience to complete the Pre-Registration at The Latest Before 24:00 On The Day Before the Exhibition, Otherwise they will not be Day. 4. Number of People Limit:…

2025 Middle East Oman Muscat Building Materials Exhibition Visitor Recording and Registration Address

The exhibition of Muscat 2025 building materials in the Middle East will take place at the Muscat International Convention and Exhibition Center in Oman on 2025.05.19-05.21. Pre-registered address Public pre-registration at Muscat Building Materials Exhibition in Oman, Middle East Ticket information Exhibition ticket2025.05.19-05.21 300.00 yuan Actual pre-registration 1. Real-Name Authentication: Almost all exhibitions require the audience to complete real-name registration in advance, fill in the real name, id number, mobile phone number and other information, and ensure that the original id card or corresponding certificate (such as passports, hong kong, macao and taiwan passes) Carried on-site Verification 2. Time-Sharing Appointment: some exhibitions Need to choose a specific Visit Date. If the supplement Period is not selected or miss, they may not be able to enter the coming 3. Pre-recorder Deadline: Some exhibitions require the Audience to complete the Pre-Registration at The Latest Before 24:00 On The Day Before the Exhibition, Otherwise they will not be Day. 4. Number of People…

2025 Polish water treatment exposure recording and recording visitors

The 2025 Polish water treatment exposure will take place at the Bydgoszcz exhibition center in Poland on 2025.05.20-05.22. Pre-registered address Pre-registration to the public of Polish water treatment Ticket information Exhibition ticket2025.05.20-05.22 600.00 yuan Actual pre-registration 1. Real-Name Authentication: Almost all exhibitions require the audience to complete real-name registration in advance, fill in the real name, id number, mobile phone number and other information, and ensure that the original id card or corresponding certificate (such as passports, hong kong, macao and taiwan passes) Carried on-site Verification 2. Time-Sharing Appointment: some exhibitions Need to choose a specific Visit Date. If the supplement Period is not selected or miss, they may not be able to enter the coming 3. Pre-recorder Deadline: Some exhibitions require the Audience to complete the Pre-Registration at The Latest Before 24:00 On The Day Before the Exhibition, Otherwise they will not be Day. 4. Number of People Limit: Group Audiences USULLY NEEED 5 OR MORE OR MORE OR…

Pakistan Solar Photovoltaic Exhibition 2025 Standing and Stand Reservation costs

2025.07.18-07.20, the highly anticipated exhibition of Pakistan Solar Photovoltaic will take place in Pakistan Lahore Expo Center. Stand type and price Standard booth: provides basic stand installations, including exhibition tables, exhibition tables, chairs, lighting, etc., suitable for small businesses or businesses participating in the exhibition for the first time. The prices vary depending on the area and the location of the stand. Light diving booth: No installation is provided. The price is calculated in square meters and also varies according to the various locations. Reservation process Complete the request form: Complete the online stand application form to provide basic information on business and stand needs. Select a stand: Select the location of the desired stand depending on the stand layout diagram and confirm the stand type and the area. Submit the request: submit the stand application form and related information, pending examination by the organizing committee. Sign a contract: once the examination is approved, the organizing committee will sign a…

Wuhan World Pet Expo 2025

2025.07.18-07.20, the Wuhan World Pet Expo 2025 should take place at the Wuhan International Expo Center. This is a major high -quality resource event in the pet supplies industry. This exhibition is an important meteorological palette for the pet supplies industry and provides companies with pet supplies an open and efficient communication platform. Wuhan World Pet Expo The Conference Journal generally contains exhibitors' lists, exhibition introductions, stands and exhibition events and other exhibition information, which is very useful for visitors who wish to establish commercial links. The newspaper generally contains the following content: Directory of exhibitors: Name of exhibitors, Stand number and contact details. Introduction of the exhibition: Basic information, scale, history and importance of the exhibition. Stand map: Present the specific location of the exhibitor in the pavilion. Simultaneous activities: Introduction to various forums, competitions and activities during the exhibition. How to get the newspaper: Download the electronic version of the conference via the official exhibition website. Get a…

2025 Exhibition of the Australian exhibition of the Gold Coast Fisheries and Fishing Tackle (time and location + How to buy tickets?)

Australian Gold Coast Fisheries and Tackle Exhibition Exhibition time: 2025.07.07.23-07.26 Exhibition room: Gold Coast Exhibition Center, Queensland, Australia, Organizer: Exhibition scale: Exhibition zone: 15,000 square meters, 10,680 visitors, 300 exhibitors, organizers: Australian Fisheries Association Association Association Association Ticket reservation guide: 1. Visit the official website of the Australian Gold Coast Fisheries and Fishing Tackle exhibition or the Juzhan.com exhibition page. 2. Click on the "Remalogue of tickets" button or "Apply" to enter the reservation page. 3. Fill in your personal information based on prompts, including the name, contact number, identification number, etc. 4. Submit an appointment request after confirming that the information is correct. 5. After receiving the notification that the appointment is successful, keep the confirmation information in the SMS, WeChat or Email. Exhibition ticket 2025.07.23-07.26 800.00 Yuan Exhibitions of Australia Gold Coast Fishing and Fishing Tackle Exhibition: Fishing products:All kinds of aquatic products, seafood and packaging productsFishing technology:Treatment, packaging, technology and fresh preservation equipment(Copyright of this content belongs…

2025 Hefei World Manufacturing Conference Hefei Industrial Exhibition Visitor Registration and precautions

The industrial exhibition of the Hefei World Manufacturing 2025 conference will take place at the Hefei Binhu International Convention and Exhibition Center on 2025.05.23-05.25. Pre-registered address Hefei World Manufacturing Conference Hefei Industrial Exhibition Pre-registration Ticket information Exhibition ticket2025.05.23-05.25 100.00 yuan Actual pre-registration 1. Real-Name Authentication: Almost all exhibitions require the audience to complete real-name registration in advance, fill in the real name, id number, mobile phone number and other information, and ensure that the original id card or corresponding certificate (such as passports, hong kong, macao and taiwan passes) Carried on-site Verification 2. Time-Sharing Appointment: some exhibitions Need to choose a specific Visit Date. If the supplement Period is not selected or miss, they may not be able to enter the coming 3. Pre-recorder Deadline: Some exhibitions require the Audience to complete the Pre-Registration at The Latest Before 24:00 On The Day Before the Exhibition, Otherwise they will not be Day. 4. Number of People Limit: Group Audiences USULLY NEEED…

2025 Zhengzhou Tourism B&B and camping equipment Exhibition of visitors and recording method

The exhibition of the B&B equipment and Zhengzhou B & B campsite in Zhengzhou will be held at the Zhengzhou International Convention and Exhibition Center on 2025.05.22-05.24. Pre-registered address Pre-registration of visitors for Zhengzhou Tourist B&B and exhibition of camping equipment Ticket information Exhibition ticket2025.05.22-05.24 30.00 yuan Actual pre-registration 1. Real-Name Authentication: Almost all exhibitions require the audience to complete real-name registration in advance, fill in the real name, id number, mobile phone number and other information, and ensure that the original id card or corresponding certificate (such as passports, hong kong, macao and taiwan passes) Carried on-site Verification 2. Time-Sharing Appointment: some exhibitions Need to choose a specific Visit Date. If the supplement Period is not selected or miss, they may not be able to enter the coming 3. Pre-recorder Deadline: Some exhibitions require the Audience to complete the Pre-Registration at The Latest Before 24:00 On The Day Before the Exhibition, Otherwise they will not be Day. 4. Number…

2025 Portugal Textile and Tabrical clothing and textile machines recording and recording methods for visitors

The exhibition of textile and clothing machines from Portugal from Portugal to Portugal will take place on 2025.05.20-05.22 at Santa Maria de Font in Portugal. Pre-registered address Pre-registration of visitors to Portugal Textile and Tabriques and Textile Machines clothes Ticket information Exhibition ticket2025.05.20-05.22 600.00 yuan Actual pre-registration 1. Real-Name Authentication: Almost all exhibitions require the audience to complete real-name registration in advance, fill in the real name, id number, mobile phone number and other information, and ensure that the original id card or corresponding certificate (such as passports, hong kong, macao and taiwan passes) Carried on-site Verification 2. Time-Sharing Appointment: some exhibitions Need to choose a specific Visit Date. If the supplement Period is not selected or miss, they may not be able to enter the coming 3. Pre-recorder Deadline: Some exhibitions require the Audience to complete the Pre-Registration at The Latest Before 24:00 On The Day Before the Exhibition, Otherwise they will not be Day. 4. Number of People…

Shanghai International Gifts and Promotal Products Exhibition 2025 Exhibitor Directory and Journal

The exhibition of international products and promotional products from Shanghai International Gifts and 2025 will be held at Shanghai New International Expo Center from 17 to 07.19 July 2025. It provides a precious communication platform for 60,000 visitors to the gift industry and 2,000 participating companies, and is an important meteorological range in the gift industry. Shanghai International Gifts and Promotal Products Exhibition Electronic Journal The Conference Journal generally contains exhibitors' lists, exhibition introductions, stands and exhibition events and other exhibition information, which is very useful for visitors who wish to establish commercial links. The newspaper generally contains the following content: Directory of exhibitors: Name of exhibitors, Stand number and contact details. Introduction of the exhibition: Basic information, scale, history and importance of the exhibition. Stand map: Present the specific location of the exhibitor in the pavilion. Simultaneous activities: Introduction to various forums, competitions and activities during the exhibition. How to get the newspaper: Download the electronic version of the…

Australia Adelaide Wine Fair 2025 Electronic Journal

2025.07.21-07.23, the highly anticipated Australian Australian exhibition will take place at the Convention and the Adelaide Exhibition Center. Australian Adelaide Wine Fair Electronics The exhibition review contains information such as exhibitors' lists, exhibition introductions, stands and simultaneous events, which are very useful for visitors who wish to establish commercial links. The newspaper generally contains the following content: Directory of exhibitors: List the names, stand numbers and contact details of all exhibitors. Introduction of the exhibition: Providing basic information, the scale, the history and the importance of the exhibition. Stand map: present the specific location of exhibitors in the pavilion. Simultaneous activities: Introduction to various forums, competitions and activities organized during the exhibition. How to get the newspaper: Download the electronic version of the conference via the official exhibition website. Get a paper edition of the review at the consultation office on the exhibition site. Buy or book a problem via the exhibition service website. Arabian Australian wine fair Exhibition time:…

2025 Philippines Manille Electric Power and Energy Exhibition Visitor Registration Method

The exposure of electricity electricity and energy of the Philippines Manila 2025 will be held at the SMX Exhibition Center in Manila, in the Philippines, 2025.05.19-05.20. Pre-registered address Pre-registration of visitors to the exposure of Manila's electrical energy to the Philippines Ticket information Exhibition ticket2025.05.19-05.20 100.00 yuan Actual pre-registration 1. Real-Name Authentication: Almost all exhibitions require the audience to complete real-name registration in advance, fill in the real name, id number, mobile phone number and other information, and ensure that the original id card or corresponding certificate (such as passports, hong kong, macao and taiwan passes) Carried on-site Verification 2. Time-Sharing Appointment: some exhibitions Need to choose a specific Visit Date. If the supplement Period is not selected or miss, they may not be able to enter the coming 3. Pre-recorder Deadline: Some exhibitions require the Audience to complete the Pre-Registration at The Latest Before 24:00 On The Day Before the Exhibition, Otherwise they will not be Day. 4. Number…

Stand and stand price in Shanghai Maternity and Baby Food Exhibition 2025

2025.07.16-07.18, the long-awaited exhibition of maternity and food for babies will be widely owned at the national center and at the Shanghai exhibition. Stand type and price Standard booth: provides basic stand installations, including exhibition tables, exhibition tables, chairs, lighting, etc., suitable for small businesses or businesses participating in the exhibition for the first time. The prices vary depending on the area and the location of the stand. Light diving booth: No installation is provided. The price is calculated in square meters and also varies according to the various locations. Reservation process Complete the request form: Complete the online stand application form to provide basic information on business and stand needs. Select a stand: Select the location of the desired stand depending on the stand layout diagram and confirm the stand type and the area. Submit the request: submit the stand application form and related information, pending examination by the organizing committee. Sign a contract: once the examination is approved,…

Ghana 2025 trade week’s exhibition guide (time + location + tickets for booking)

Ghana trade week Exhibition time: 2025.07.07.22-07.24 Exhibition hall: Accra Convert and Exhibition Center, Ghana, Organizer: Castle RD, Accra, Ghana Exhibition Scale: Exhibition area: 8,500 square meters, 7,300 visitors, 148 exhibitors, organizers: mie group mie Ticket information: Exhibition ticket 2025.07.22-07.24 300.00 Yuan Ticket reservation guide: 1. Visit the JUZHAN.COM exhibition page or the official website of the Ghana trade week. 2. Click on the "Remalogue of tickets" button or "Apply" to enter the reservation page. 3. Fill in your personal information based on prompts, including the name, contact number, identification number, etc. 4. Submit the request after confirming that the information is correct. 5. After receiving the notification that the appointment is successful, keep the confirmation information in the SMS, WeChat or Email. Introduction of Ghana Trade Week: China Trade Week Ghana (CTW Ghana) is the largest and most influential week of the Chinese of Ghana trade. China Trade Week is a B2B fair that hopes to establish direct commercial links…

Taizhou Electric Veho Motorcycle and Parts Exhibition 2025 Time and rental

Taizhou Electric Veho Motorcycle and Parts Exhibition Exhibition time: 2025.07.26-07.28 Exhibition room: Taizhou International Expo Center Organization address: n ° 588, Xinhai Road, Jiaojiang district, Taizhou City Exhibition Scale: Exporition or International Expo Center on 2025.07.26-07.28, offering a precious communication platform for 15,000 industry visitors Electric vehicles and 450 exhibitors. Taizhou Electric Veho Motorcycle and Parts Exhibition Exhibition Porce: Mechanical and electrical productsPumping productsMotor productsIndustrial automation robotCNC machineLaser metal cutting Introduction of the exhibition: Taizhou Electric Veho Motorcycle and Parts Exhibition (EMP) is a major event in the electric vehicle and motorcycle industry. Dedicated to the supply of manufacturers of electric vehicles and motorcycles, suppliers, dealers and enthusiasts with a communication, display and cooperation platform. The exhibition will bring together innovative technologies, leading brands and latest industry products, and will show future development trends in electric and motorcycle vehicle industries.With the implementation of the new standard national policy and the upgrading of consumer demand, two -wheeled electric vehicle products are…

Standing fees and stand of advertising panels and digital signaling exhibition in Sao Paulo, Brazil

The Brazilian exhibition of São Paulo advertising panels and the 2025 digital exhibition will be held at the Northern Exhibition Center in São Paulo, Brazil, from 16 to 07.19 July. Juzhan.com provides a reservation of exhibition stands, a stand application and other business services that intend to participate. Stand type and price Standard booth: provides basic stand installations, including exhibition tables, exhibition tables, chairs, lighting, etc., suitable for small businesses or businesses participating in the exhibition for the first time. The prices vary depending on the area and the location of the stand. Light diving booth: No installation is provided. Exhibitors can design and build stands by themselves, which are suitable for companies that wish personalized screens. The price is calculated in square meters and also varies according to the various locations. Reservation process Complete the request form: Complete the online stand application form to provide basic information on business and stand needs. Select a stand: Select the location of…

Australian Fisheries and Fisheries Exhibition Guide

Australian Gold Coast Fisheries and Tackle Exhibition Exhibition time: 2025.07.07.23-07.26 Exhibition room: Gold Coast Exhibition Center, Queensland, Australia, Organizer: Exhibition scale: Exhibition zone: 15,000 square meters, 10,680 visitors, 300 exhibitors, organizers: Australian Fisheries Association Association Association Association Ticket information: Exhibition ticket 2025.07.23-07.26 800.00 Yuan Ticket reservation guide: 1. Visit the JUZHAN.COM exhibition page or the official website of the Australian Fishing and Fishing of Gold Coast. 2. Click on the "Remalogue of tickets" button or "Apply" to enter the reservation page. 3. Fill in your personal information based on prompts, including the name, contact number, identification number, etc. 4. Submit the request after confirming that the information is correct. 5. After receiving the notification that the appointment is successful, keep the confirmation information in the SMS, WeChat or Email. Introduction of the exhibition: Australian fishing and tackle on the Gold Coast (The Australian Fishing Trade Association is the only official fishing, navy and outdoor fair in Australia.The exhibition attracts professionals…

2025 Munich Outdoor Products Exhibition Visitor Registration and Precautions

The exhibition of outdoor products from Munich 2025 in Germany will take place at the New International Expo Center in Munich, Germany, 2025.05.19-05.21. Pre-registered address Pre-registration to the public in the Munich Outdoor Products Fair in Germany Ticket information Exhibition ticket2025.05.19-05.21 4000.00 yuan Actual pre-registration 1. Real authentication: Almost all exhibitions require the public to end in advance a real name, fill out the actual name, the identification number, the mobile phone number and other information, and ensure that the original identity card or the corresponding certificate (such as the passport, Hong Kong, Macao and Taiwan Pass) should be transported on the date of appointment on site. Place 3. Pré-registration deadline: Some exhibitions require the public to end the pre-registration no later than 24 hours before the day of the exhibition, otherwise they will generally not be able to enter the place on the same day. Entrance verification 1. All viewers must complete their actual reservation via their recorded mobile…

Pakistan Solar Photovoltaic Exhibition 2025 Booth Card and Booth Application

Pakistan Solar Photovoltaic Exhibition 2025 will be held at Lahore Expo Center, Pakistan, from 18 to 07.20 July, 2025. Juzhan.com provides a reservation of exhibition stands, a stand application and other services to companies that intend to participate in the exhibition. Stand type and price Standard booth: provides basic stand installations, including exhibition tables, exhibition tables, chairs, lighting, etc., suitable for small businesses or businesses participating in the exhibition for the first time. The prices vary depending on the area and the location of the stand. Light diving booth: No installation is provided. The price is calculated in square meters and also varies according to the various locations. Reservation process Complete the request form: Complete the online stand application form to provide basic information on business and stand needs. Select a stand: Select the location of the desired stand depending on the stand layout diagram and confirm the stand type and the area. Submit the request: submit the stand application…

2025 Japan Education Equipment Exhibition Booth Price and reservation of stands

The Japan Education Equipment exhibition is about to be organized. To help exhibitors book their stands gently, this article provides a detailed guide for booking stands. Stand type and price Standard booth: provides basic stand installations, including exhibition tables, exhibition tables, chairs, lighting, etc., suitable for small businesses or businesses participating in the exhibition for the first time. The prices vary depending on the area and the location of the stand. Light diving booth: No installation is provided. The price is calculated in square meters and also varies according to the various locations. Reservation process Complete the request form: Complete the online stand application form to provide basic information on business and stand needs. Select a stand: Select the location of the desired stand depending on the stand layout diagram and confirm the stand type and the area. Submit the request: submit the stand application form and related information, pending examination by the organizing committee. Sign a contract: once the…