The global trade landscape has always been delicate, and recent events such as the Red Sea crisis and the Baltimore Bridge accident have added complexity. The sudden closure of China’s Ningbo Port due to a YM Mobility container explosion was initially considered a major disruption, but the port quickly reopened within 80 hours, mitigating some of the expected consequences.

See also: Necessary measures to reduce the impact during Ningbo Port closure

The closure of Ningbo Port, which accounts for nearly 29% of China’s total ship traffic, initially appeared to have a significant impact on global trade, but the rapid resolution of the situation limited its impact. However, there were some supply chain disruptions during the brief outage.

The strategic importance of Ningbo Port

The Port of Ningbo remains an important player in global logistics, facilitating the flow of goods between the Far East and major global markets such as Europe and the United States.

In 2023, the container throughput of Ningbo Port reached 33.35 million TEUs (20-foot equivalent units), playing an important role in international trade.

The suspension of operations at the Ningbo plant had an immediate impact, particularly in terms of delays and logistical challenges.

Rising costs and delays: the immediate consequences

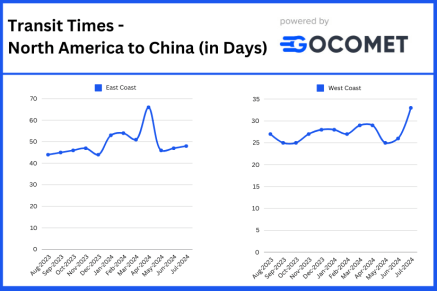

Although ports reopened within a short time, the brief closure triggered disruptions on global trade routes. While the China-Europe corridor was initially expected to bear the brunt of the impact, some changes in shipping times were also seen on transpacific routes. Notably, shipping times from North America to China fluctuated during this period.

West Coast transit times increase from 25 days in September 2023 to 33 days in July 2024. East Coast transit times increase from 45 days in September 2023 to 48 days in July 2024.

While these delays were relatively brief, they highlight the fragility of global supply chains and underscore the importance of strategic planning to mitigate such disruptions.

Given these changes, the key question is: How should companies adjust their strategies to manage these increased delays and maintain supply chain efficiency?

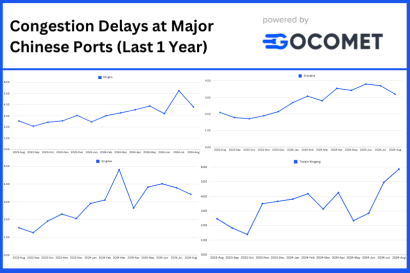

Domino effect: How Shanghai responds

With the suspension of Ningbo Port, pressure on surrounding ports, especially Shanghai Port, has also increased. Shanghai Port handles nearly 43% of China’s cargo volume and is now facing unprecedented congestion. In the past year, Traffic congestion in Shanghai is getting worseCoupled with increased freight volumes in Ningbo, delays are expected to increase further. This situation has created a major bottleneck in the global supply chain.

The challenge now is how to manage these bottlenecks while maintaining supply chain efficiency and reliability.

Qingdao’s role: a viable alternative

Amid these challenges, Qingdao Port has emerged as a key alternative. With a throughput of 23.7 million TEUs in 2023, Qingdao Port recently expanded its capacity by 20% to cope with the overload of Ningbo Port. This is not only to absorb the additional traffic, but also to ensure the stability and continuity of global trade.

Leveraging Qingdao’s increased production capacity

Businesses can reduce the risk of disruption by shifting logistics to Qingdao; by leveraging its expanded capacity and strategic location, they can maintain supply chain continuity and reduce shipping delays.

Prepare for the next step

Although the impact of the Ningbo Port incident was not as severe as initially expected, it is a reminder of the fragility of global supply chains. Companies must continue to focus on diversified logistics strategies, embrace innovation, and build stronger networks to cope with potential disruptions.

Although Ningbo’s rapid resumption of work has limited the short-term impact, this incident has once again highlighted the need for mid- to long-term strategic planning for supply chain management. By integrating advanced technologies such as automation and real-time tracking, and building strong partnerships, companies can better prepare and adapt to future challenges.

Gautam Prem Jain Chief Executive Officer cometa logistics resource management software platform that helps large enterprises transform their supply chain operations.

Leave a Reply Cancel reply

You must be logged in to post a comment.