How 3D and 2.5D IC packaging solutions enhance electronics

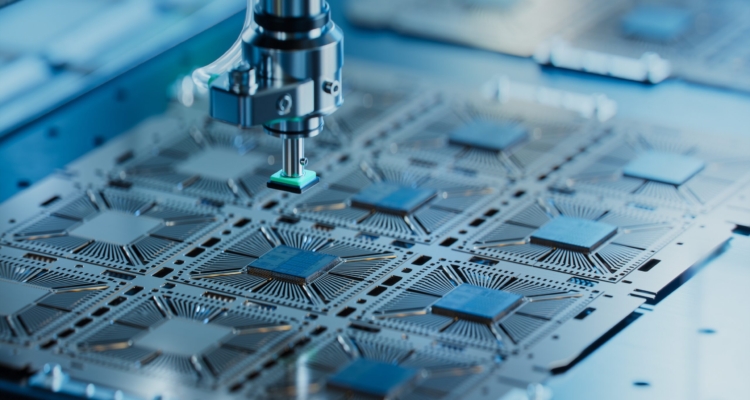

Compared to traditional packaging methods, 3D and 2.5 ICS offer more compact form factors and minimize power consumption, which is important for mobile devices and other space-constrained applications. Key players in the market are focused on adopting inorganic growth strategies such as acquisitions and mergers to develop advanced technologies for manufacturing 3D IC and 2.5D IC packaging, which is expected to drive the global 3D IC and 2.5D IC packaging market during the forecast period. Also Read: How Semiconductor Packaging Shapes Tomorrow’s Technology 3D IC and 2.5D IC packaging market: improving semiconductor capabilities 2.5D and 3D packaging technologies are used to package multiple integrated circuits in a single package. To achieve very high chip-to-chip connection density, two or more active semiconductor chips are arranged side by side on a silicon interposer in a 2.5D configuration. Chip stacking is used in 3D structures to incorporate active chips for the shortest connections and smallest package footprint. In recent years, 2.5D and 3D…