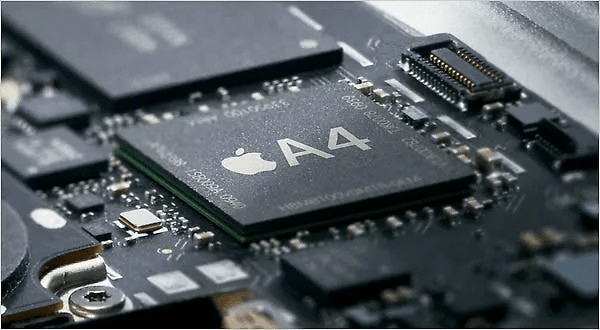

Apple will move to in-house developed Bluetooth chips

Apple is working to reduce its reliance on outside suppliers, switching to its own custom-designed Bluetooth and Wi-Fi connectivity chips in its devices starting next year. According to Bloomberg, the new chip, tentatively named Proxima, is planned to be used in Apple iPhones and smart home devices produced in 2025. Also read: Apple starts assembling iPads in Vietnam In a strategic move to achieve technological self-reliance, Apple plans to produce these chips through TSMC. It is worth noting that Taiwan is already the leading exporter of the global electronic chip market. According to statistics, exports will reach US$317.5 billion in 2023. IndexBox platform. Apple's internal innovation extends to their server chips, as they announced at their annual developer conference in June that their development efforts are aimed at enhancing artificial intelligence capabilities in their products. The shift fits Apple's broader strategy of replacing components from suppliers such as Broadcom and Qualcomm, with whom it has previously had significant partnerships. That…

Supply Chain Forecast 2025 – Global Trade Magazine

2024 is a stark reminder of the inherent fragility of global supply chains. Natural disasters, coupled with geopolitical and economic instability and ongoing inflation, create a challenging operating environment. At the same time, rising cyber threats highlight the need for strong digital security in supply chains. These accumulated lessons underscore the importance of resilient supply chains in driving growth and efficiency while managing uncertainty. Also read: Artificial Intelligence – How it is shaping and redefining logistics As a result, supply chain leaders are accelerating their shift from reactive approaches to more proactive strategies designed to protect their operations and build lasting resiliency. Artificial intelligence (AI) is one of the most promising tools in this transformation. Artificial intelligence is already starting to revolutionize supply chains, allowing leaders to better predict everything from demand fluctuations to procurement delays. By 2025, AI will transcend its “must-have” status and become an indispensable tool for chief supply chain officers (CSCOs) as they seek to drive…

The role of artificial intelligence in streamlining operations and reducing costs

Artificial Intelligence and Traditional Automation Traditional automation involves rule-based systems for repetitive tasks without human intervention, done through tools such as scripts or data entry. While it is effective for simple tasks, it lacks adaptability and decision-making capabilities beyond set scenarios. In contrast, AI-driven automation uses artificial intelligence to learn from data over time, handling complex tasks such as pattern recognition and prediction. It can analyze large data sets, identify trends and make real-time adjustments, capabilities that traditional automation lacks. The main difference is flexibility and intelligence, as AI-driven automation can process unstructured data, evolve through machine learning, and provide insights, making it ideal for dynamic applications such as predictive maintenance and demand forecasting. Also read: The Impact of Automation and Artificial Intelligence on Supply Chain Efficiency: Changing the Logistics of the Future Integration of artificial intelligence and business systems Cross-departmental AI integration involves embedding AI tools into CRM systems to gain insights into customer behavior and into ERP systems…

Leveraging automation and machine learning to ease port

In an increasingly fragmented global supply chain, ongoing port congestion has reached a tipping point, with many major ports struggling to handle incoming and outgoing cargo. Highlight The congestion level of each port is as follows: in the first half of 2024, the average waiting time at Durban Port is 8 days; the average waiting time at Ningbo-Zhoushan Port is 6.1 days; the average waiting time at Vancouver Port is 4.28 days; the average waiting time at Los Angeles Port is 3.6 days; and the average waiting time at Chittagong Port is 3.4 days. In addition, Estimated At risk is $131 billion in trade at ports such as Singapore, Tanjung Pelepas and Port Klang, where cargo has been severely backlogged in recent months, largely because ships have been diverted around the Red Sea. See also: Riding the wave: Examining the looming threat of port congestion As congestion periods become more frequent, costly and prolonged, targeted deployment of automation can streamline…

3 ways smart IoT technology can help tackle climate change

Supply chains have undergone rapid changes, with climate change emerging as one of the most critical disruptors. As extreme weather events continue to increase in frequency and intensity, they pose an unprecedented threat to global supply chains. Also Read: IoT in Warehouse Management Market: Revolutionizing Logistics with Connected Devices According to the World Meteorological Organization, weather-related disasters have increased fivefold over the past 50 years, resulting in more than $3.64 trillion in global economic losses. These disruptions are forcing businesses to rethink their risk management strategies and adopt more advanced, resilient approaches that go beyond traditional methods. Climate risk challenges in the supply chain Climate change affects supply chains in a variety of ways, including extreme weather, rising temperatures and shifting precipitation patterns that can disrupt manufacturing processes, delay shipments and complicate logistics. A stark example is the 2021 Texas winter storm, which caused widespread supply chain disruptions. Manufacturing and energy production came to a standstill, leading to ripple effects…

The future of autonomous shipping: from coastal routes to

The concept of autonomous ships sailing along coastlines, inland waterways and even on the high seas is no longer confined to science fiction. During a recent CONNECTING PORTS talk show hosted by HPC Hamburg Port Consulting (HPC), experts came together to discuss the emerging reality of autonomous shipping and highlight how this technology is gradually becoming part of modern logistics. Also read: Eventual autonomous shipping faces huge hurdles The forum was moderated by Christina Prieser, Associate Partner at HPC, and featured insights from three industry leaders: Ørnulf Jan Rødseth, Managing Director of the Norwegian Forum for Autonomous Ships (NFAS), Marc Holstein, Head of the SEAFAR Remote Operations Centre in Antwerp, and Antoon van Collie, CEO of ZULU Associates. Rødseth shared Norway’s pioneering initiatives in semi-autonomous shipping, including the world’s first semi-autonomous container ship, which will begin transporting cargo in spring 2022. Operating with a minimal crew and controlled remotely, the vessel demonstrates the practical application of autonomous technology in coastal…